The pressure control system is incorporated into the gas cleaning plant and precisely regulates the furnace pressure. However, should the pressure exceed the maximum permissible value, the excess gas must be removed in a controlled and safe manner. This is achieved with the safety valve B11 which limits the maximum pressure in the gas system through a pre-defined immersion of a water seal and vents to atmosphere.

The pressure control system is incorporated into the gas cleaning plant and precisely regulates the furnace pressure. However, should the pressure exceed the maximum permissible value, the excess gas must be removed in a controlled and safe manner. This is achieved with the safety valve B11 which limits the maximum pressure in the gas system through a pre-defined immersion of a water seal and vents to atmosphere.

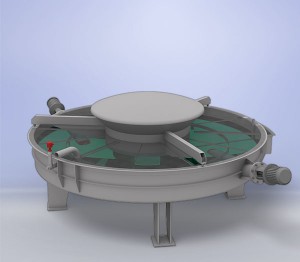

Functionality of the Safety Valve

From the quench cooler a duct leads to the safety valve and ends under a bell shaped dome. The edges of the dome are evenly immersed in the sealing water thus creating a gas tight water seal. This ensures that at underpressure conditions no ambient air is drawn into the system, while no CO is vented at overpressure below the maximum gas pressure.

Accurate Adjustment of the Limit Pressure

The immersion depth of the bell can be accurately adjusted to the desired maximum pressure of the gas system. To maintain the water level process water is continually added and drains over an integrated weir. During a power failure or disruption of the process water flow, the emergency water tank of the gas cleaning plant maintains the required water level.

Solids carried over by the dirty process gas are kept in suspension by turbulence pumps or built-in agitators and are then carried away with the drain water towards the concrete sump.