Rotary Hood Valve B12 (emergency stack) and B13 (gas cleaning)

Rotary Hood Valve B12 (emergency stack) and B13 (gas cleaning)

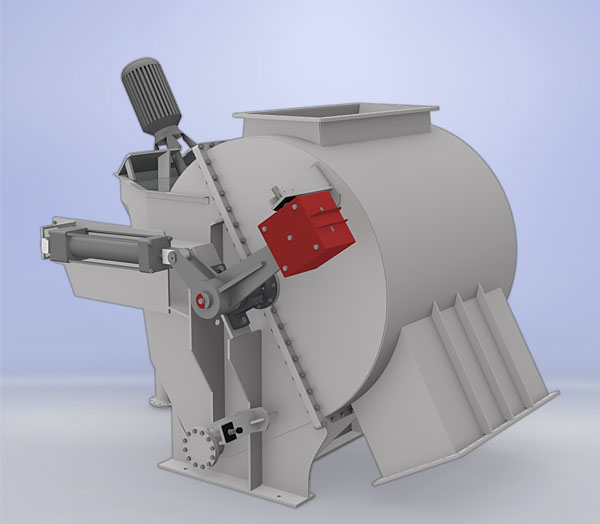

The rotary hood valves B12 and B13 are durable, gas tight shut-off valves for isolating process gas paths even under extreme conditions regarding high temperature and dust load. In closed positon the integrated rotary hood is immersed in the sealing water thus creating a gas tight water seal. In the open position the gas has free flow thus no additional pressure drop arises and the units are not sensitive to dirty process gas i.e. they are jam proof.

A constant supply of process water which drains via an integrated weir ensures that the immersion is maintained at all times. During emergency situations the water is supplied from the emergency water tank. Solids carried over by the dirty process gas are kept in suspension by a built-in agitator and are then carried away with the drain water towards the concrete sump.

Rotary Hood Valves for Gas Path Control

During clean gas operation the process gas flows via the rotary hood valve B13 (gas cleaning) from the quench cooler to the clean gas section. At this stage the second valve B12 (emergency stack) isolates the gas path to the emergency stack. The two valves are operated with pneumatic cylinders, which rotate the hoods between the respective positions open/closed. The two valves are interlocked both pneumatically and electrically to ensure that one valve must first close before the other can open.