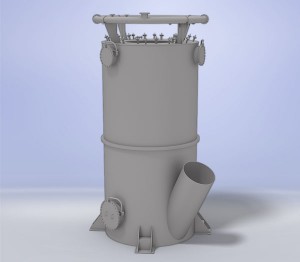

Quench Cooler W10 & Cooling and Scrubbing Tower W14

The off-gas of the smelting furnace is routed to the quench cooler W10 via the furnace off-gas duct. Here, the hot and dust-laden furnace gas is sprayed with water from numerous spray nozzles, cooling down the gas close to the saturation temperature of about 80 °C and scrubbing out coarse dust. Gas and water flow within the quench cooler are co-current with the inlets at the head and the outlets in the bottom sections of the vessel.

The off-gas of the smelting furnace is routed to the quench cooler W10 via the furnace off-gas duct. Here, the hot and dust-laden furnace gas is sprayed with water from numerous spray nozzles, cooling down the gas close to the saturation temperature of about 80 °C and scrubbing out coarse dust. Gas and water flow within the quench cooler are co-current with the inlets at the head and the outlets in the bottom sections of the vessel.

Gas Cooling and Cleaning

The water saturated process gas leaving the quench cooler is routed to the cooling and scrubbing tower W14 via the rotary hood water seal B13 “gas cleaning“. Here further gas cooling takes place to about 35 °C as well as scrubbing out of medium sized dust particles. Process water is injected into this counter-current gas cooler on several levels while the process gas is drawn through the vessel from bottom to top, and then subsequently routed to the Disintegrator through a down pipe.

Advantages of Spray Cooling

- utilisation of the entire vessel volume of the gas coolers as reaction chamber

- efficient heat transfer due to high surface area generated of the water droplets

- uniform gas cooling over the full vessel cross-section

- optimized capture and segregation of dust due to high droplet surface area

- low risk of fouling as the gas coolers are designed as cylindrical vessels including permanent flushing of the inside tank walls

Drain of Used Process Water

The gas cooler vessels are open-ended at the base and are immersed in water-filled foundation/sump combinations. A constant water level is maintained in the sump due to the overflow weirs, thus creating a gas tight seal between the inside gas phase and the external atmosphere.

To prevent captured solid particles from forming sediment in the sump below the gas coolers, agitators are installed in near proximity to provide the necessary turbulence in the water.